Quality Control

Our company fully implements comprehensive quality management and quality systems, holding the National Administration of Quality Inspection's TS License for Manufacturing Pressure Piping Components, ISO 9001 certification for quality, environment, and occupational safety & health, as well as API6D, API607 Fire Protection Certification, API6FA, CE certification, Russian CU-TR and RTN certificates, and Canada's CRN certification, among others.

We have 37 quality inspection personnel, all of whom hold internationally recognized certifications such as the U.S. Society for Nondestructive Testing (SNT-TC-1A) certificate and international welding qualifications. Additionally, they possess national-level NDT Level II certifications, along with qualifications in metrological calibration for advanced measuring equipment.

Our facility is equipped with over 30 advanced testing instruments, providing comprehensive performance-testing capabilities. We can evaluate a wide range of performance metrics for steam traps, including flow characteristics, as well as assess critical parameters like overcapacity in emergency shut-off valves and sealing/pressure resistance in general-purpose valves.

Moreover, our company boasts a fully equipped physicochemical measurement system, ensuring accurate traceability of measurement values and guaranteeing the precise chemical composition of all metal materials used in our processes.

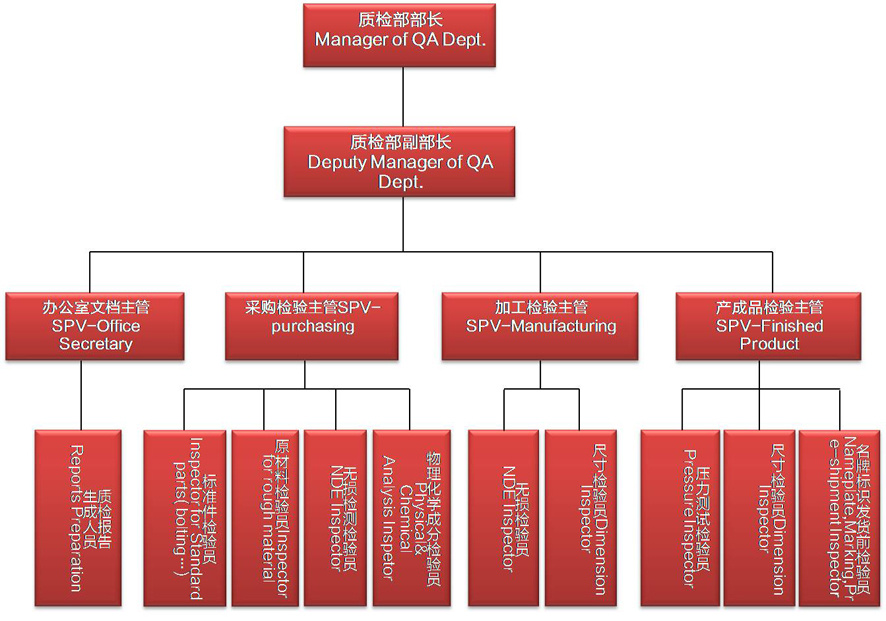

Quality Control Department Organizational Chart

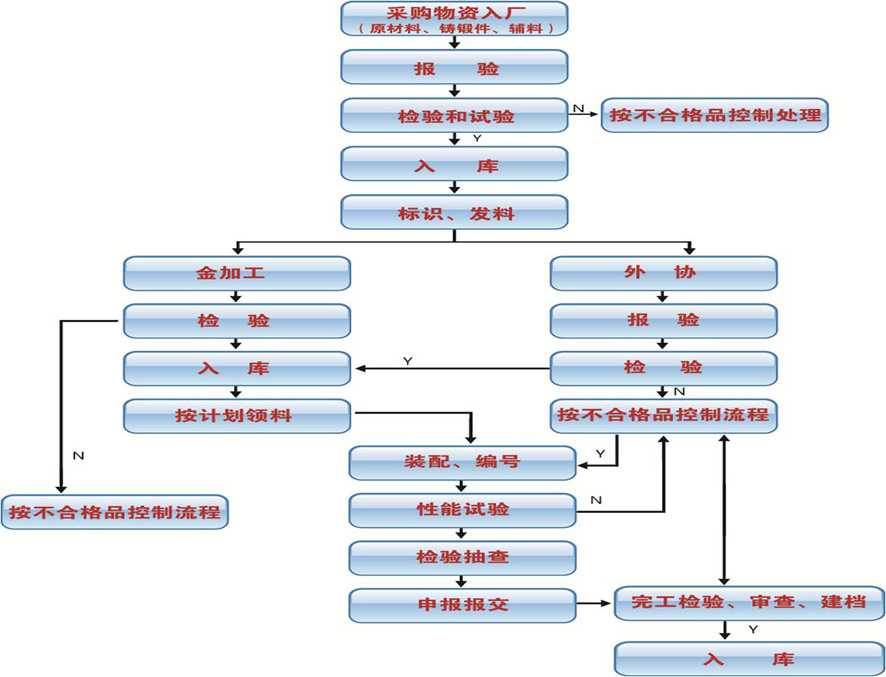

Quality Control Flowchart

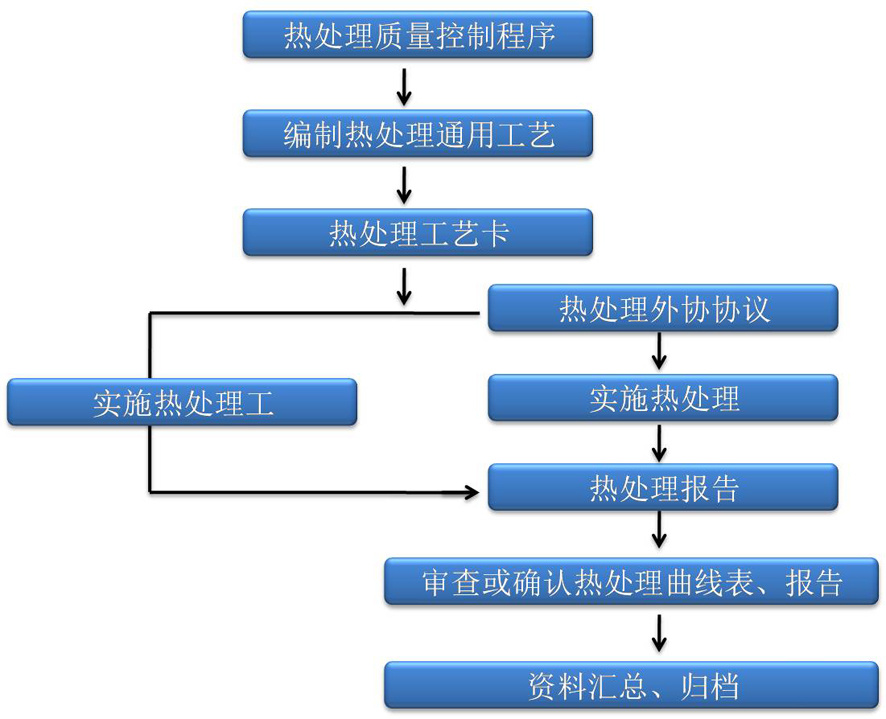

Special Quality Control – Heat Treatment Quality Control

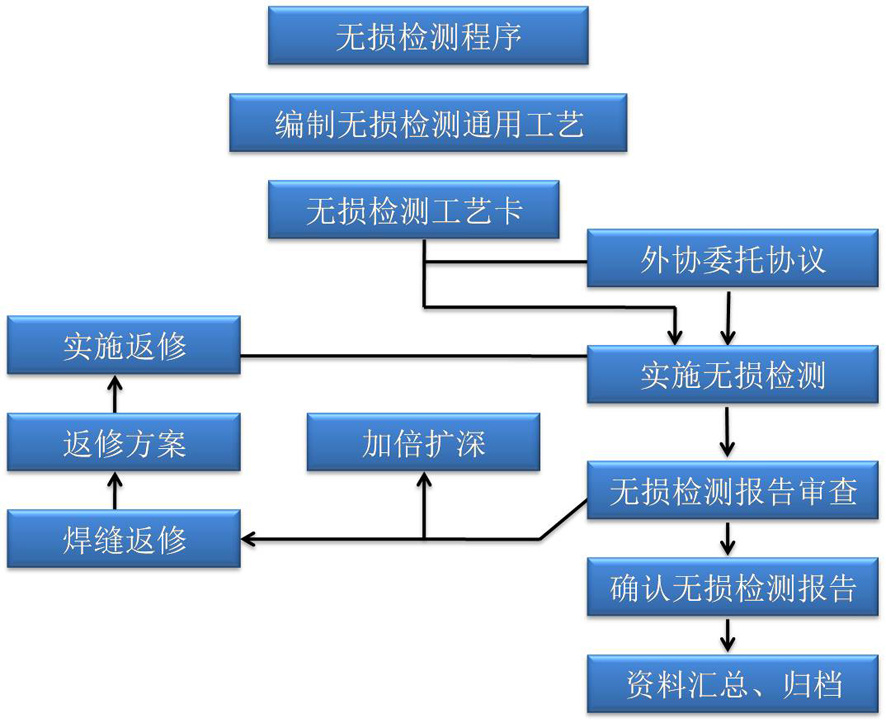

Specialized Quality Control – Non-Destructive Testing Quality Control